Residues Recovery Platform - (BAP Steel + ACO Iron)

BAP Steel and ACO Iron together form two complementary and highly synergistic material platforms designed to prevent raw material leakages within steelmaking operations.

BAP Steel functions as a metallic platform, capable of aggregating not only steel powder recovered from sludge / ESP Dust, but also additional fine metallic streams generated across the steel mill. In parallel, ACO Iron operates as an oxide platform, integrating multiple oxide-bearing residues into a single circular raw material stream.

Working in conjunction, these platforms act as a centralized material recovery system, enabling the systematic reintegration of metallic and oxide values back into the steelmaking process.

ACO Iron

An acronym derived from the Portuguese term Aglomerado Circular de Óxidos (Circular Oxides Agglomerate), ACO Iron is an oxide-based product with typical chemical compositions presented in Table A for carbon steel plants and in Table B for stainless steel plants.

As ACO Iron is predominantly composed of particles with a grain size below 45 micrometers, it can be processed either as pellets or briquettes, while maintaining, in both configurations, the physical and chemical properties required for reduction processes, as presented in Table C.

For steel plants operating Electric Arc Furnaces (EAF), ACO Iron may be engineered to function as a self-reducing iron source, enabling direct charging into the EAF, including stainless steel production. This design flexibility increases the strategic value of ACO Iron within global steelmaking raw material management.

In steel plants equipped with integrated residue regeneration processes—such as oil removal from oily residues, recovery of materials from industrial landfills, pellet fines, sinter fines, blast furnace sludge and other oxide-rich residues—ACO Iron enables the aggregation of these different material streams into a single regenerated product.

This operational flexibility promotes greater synergy in Circular Economy Loop Closure, reduces the leakage of valuable materials throughout the steelmaking process and directly contributes to the reduction of the environmental footprint of steel production.

BAP Steel

An acronym derived from the Portuguese term Briquete de Aço Puro (Pure Steel Briquette), BAP Steel is a metallic briquette composed in its majority of metal extracted and isolated from the coarse fraction of steelmaking sludge or from the coarse fraction of ESP dust.

The Green Table presents the typical average chemical composition of BAP Steel for carbon steelmaking operations, while the Gold Table below presents corresponding average values for stainless steelmaking operations.

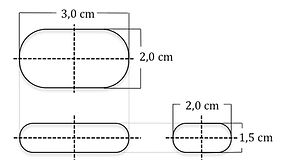

The mechanical features and reference dimensions of BAP Steel are shown in the image below and are fully compatible with handling, transportation and direct charging into BOF, AOD or Electric Arc Furnaces (EAF).

BAP Steel – Mechanical Performance and Steelmaking Usability

.jpeg)

.jpeg)

BAP Steel

Reference Briquette Dimensions

Briquette geometry and dimensions can be customized according to costumer process requirements.

All data shown are derived from real industrial reference cases using HpM regeneration technologies.

Despite the use of comparable equipment platforms, steel plants differ in operational regimes, feed material availability, and residue handling practices. As such, while HpM processes are inherently replicable, final process configurations must be engineered to align with the specific conditions of each steelmaking operation.

.jpeg)

.jpeg)

ACO Iron – Physical Properties and Steelmaking Applicability

.jpeg)

ACO Iron, produced from oxides recovered from the coarse fraction of steelmaking sludge or ESP dust, after the controlled reduction of its zinc content, presents high flexibility for steelmaking applications, even when derived exclusively from fine sludge.

The first and most direct application is its use in blast furnaces or reduction reactors. The table of physical characteristics for carbon steel ACO Iron demonstrates its mechanical strength under reducing conditions as well as its reducibility index, both of which are very close to those observed for ACO Iron derived from stainless steel residues.

.jpeg)

.jpeg)

In integrated plants equipped with sintering systems, ACO Iron can be used without thermal treatment, in its green state, as sinter feed. Under these conditions, the material no longer generates fine particulates that could impair operation. Its agglomeration within a particle size range of 8 to 12 mm is recommended, ensuring proper sinter bed permeability and operational stability.

A third alternative consists of the controlled addition of fixed carbon from renewable sources to ACO Iron, adjusted according to the quantities and types of iron oxides present in carbon steel residues and, in the case of stainless steel, to the observed alloy oxides, mainly chromite. In this configuration, ACO Iron can be directly charged into Electric Arc Furnaces (EAF), partially replacing both DRI and scrap. This solution is particularly attractive for stainless steel plants, which in most cases do not operate blast furnaces.

.jpeg)