HpM's Technical Background

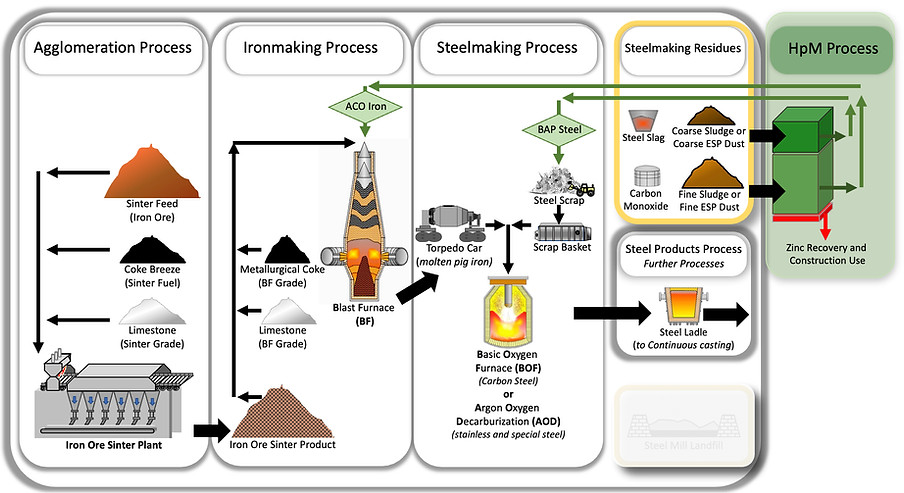

HpM’s technical foundations originate from decades of practical experience across mineral processing and metallurgical operations, spanning from ore beneficiation and equipment manufacturing to steelmaking and alloy production. This background enabled a systemic understanding of material flows across the steel value chain, from raw mineral resources to refined metallic products.

Through this perspective, HpM identified a significant circular economy opportunity within steelmaking residues that are rich in iron and alloy units, yet technically unsuitable for direct reintegration into conventional steelmaking routes. Among these residues, Basic Oxygen Furnace (BOF) sludge became the primary focus of investigation.

During steel refining in BOF and AOD converters, high-energy oxygen blowing generates an intense metal–slag emulsion. Fine metallic droplets and oxide particles are entrained into the off-gas stream and subsequently captured by gas-cleaning systems. These residues consist predominantly of iron and alloy units, distributed across different oxidation states and particle size. The image below shows two illustrations of BOF and AOD gas cleaning systems: (a) wet gas cleaning system (forming coarse and thin sludge and (b) electrostatic precipitator forming coarse and thin dust.

Within steelmaking sludge, natural density-based segregation occurs. Coarser fractions tend to concentrate higher metallic steel content, while finer fractions are predominantly oxidized and enriched in contaminants such as lime, zinc and alkalis. This physical and chemical heterogeneity represents a fundamental limitation for conventional recycling routes.

In plants equipped with sinter facilities, partial reuse of sludge fractions is possible through controlled blending, primarily to manage zinc circulation. However, significant technical constraints remain. Sintering systems are designed to operate with sinter feed (iron ore) and other raw materials (lime and coal) in the 2–12 mm particle size range, whereas steelmaking sludge typically presents mean particle sizes around 0.15 mm for coarse fractions and below 0.04 mm for fine fractions. This mismatch increases dust generation, disrupts bed permeability and complicates material homogenization.

Additionally, metallic steel contained in sludge is effectively downgraded when routed through sintering and blast furnace processes. Although already refined steel, it is treated as raw material, re-agglomerated with iron ore and reintroduced into high-carbon reduction routes. This results in redundant energy consumption, increased operational complexity and unnecessary carbon emissions.

These technical limitations have historically led to landfill disposal as the primary destination for fine sludge fractions, even in steel plants with advanced recycling infrastructure.

This gap between material value and technical feasibility created the opportunity for HpM to develop a selective separation approach capable of isolating metallic steel from oxide phases while managing contaminant circulation within the steel plant.

Metallic particles present in steelmaking sludge typically occur as micro-spherical droplets, formed by surface energy minimization during suspension within the high-energy converter environment. Leveraging this physical characteristic, HpM developed proprietary mechanical processes and equipment capable of disaggregating sludge and selectively isolating metallic micro-spheres. HpM's process is capable to send the metallic particles (BAP Steel) to Steel Making Process directly as scrap, without loosing the added value of the present steel in the sludge or ESP Dust. The Oxides from Coarse Sludge or Coarse Dust with the Thin Sludge or Thin ESP dust also are agglomerated without any binder and can be directly used in the Blast Furnace. The amount of residues is drastically reduced to a range of 5% up to 10% of the sludge. The image below shows how HpM's technology provides a Circular Economy loop preventing leakage of materials from Coarse Sludge or ESP Dust and from Thin Sludge or Thin ESP Dust.

BOF and AOD Gas Cleaning System Types

Typical BOF and AOD Features

Electrostatic Precipitator System - ESP Dust Formation

Wet Gas Cleaning System - Sludge Formation

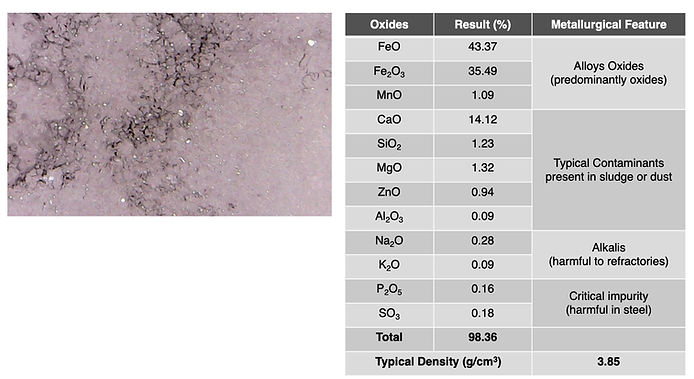

Microscopic Image and Chemical Composition of

Corase Steelmaking Sludge

Microscopic Image and Chemical Composition of

Fine Steelmaking Sludge

General Example of Typical Sintering Plant Sludge/Dust Use

HpM's Circular Economy Loop for Steel Mill Sludge/Dust

Microscope image at 1,200× magnification

.jpeg)

Microscope image at 1,200× magnification