Industrial Agglomeration: Engineering, Safety and Performance

The metallurgical processes involved in steelmaking require raw materials to meet well-defined physical and chemical specifications. Parameters such as particle size distribution, mechanical strength, bulk density, chemical composition, and thermal behavior are essential to ensure the safe and reliable use of materials across the different stages of steel production. Without adequate physical characteristics, even chemically regenerated materials cannot fully realize their value in steelmaking operations and may present operational, safety, or environmental limitations.

HpM’s technologies for residue regeneration and resource valorization focus strongly on improving the chemical characteristics of materials. Within this framework, agglomeration plays a strategic role by adapting these materials to the physical and operational requirements of steelmaking processes. Key parameters include product size, density, the presence or absence of binders, binder type, mechanical strength, fines generation, and thermal stability during processing.

Through its own technological developments, HpM has built solid expertise in industrial-scale agglomeration, mastering routes such as briquetting, pelletizing, and extrusion, both cold and hot, with or without binders. Each solution is defined based on the intrinsic characteristics of the material and the technical, economic, and operational requirements of the client.

Operational safety is a central pillar of HpM’s developments. Factors such as ignition point, thermal stability, safe handling, and operational risk mitigation are carefully evaluated in the design of briquettes and agglomerated products, ensuring their safe use throughout all stages of the steelmaking value chain.

HpM’s approach to agglomeration is driven by engineering-based decision making, in which different process routes and operating scales are evaluated before defining the final product. This methodology ensures that each material is transformed into an agglomerate that is technically stable, operationally safe, and fully aligned with steelmaking requirements.

Physical Testing and Evaluation of Industrial Agglomerates

Agglomeration Systems and Processes Applied by HpM

.jpeg)

.jpeg)

Image (A)

Image (B)

Image (C)

Image (A) shows equipment used for the Shatter Test, applied to evaluate the mechanical strength and impact resistance of agglomerates during handling and transportation.

Image (B) presents a system for softening-under-load and reduction testing under controlled atmosphere, used to assess key parameters such as RI (Reduction Index) and RDI (Reduction Degradation Index), ensuring stable physical and chemical behavior during reduction processes.

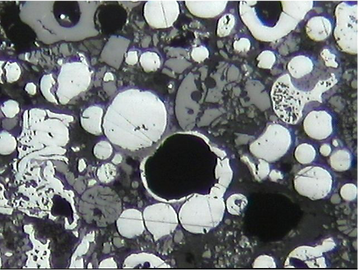

Image (C) shows a metallographic analysis of BAP Steel, a binder-free steel briquette, used to evaluate the internal structure and metallurgical quality of the agglomerated material.

Metallurgical Agglomerates Produced Through

Different Technological Routes

.jpeg)

Image (D)

Image (E)

Image (F)

Image (D) presents, at pilot plant scale (4 tonnes per hour), the pelletizing process of ACO Iron, contaminant-free iron oxides recovered from fine steelmaking sludge. This stage allows the validation of operational parameters, physical stability, and material behavior at near-industrial scale.

Image (E) shows a laboratory extruder, used in combination with pelletizing and briquetting processes to evaluate different agglomeration routes and define the most suitable solution for each type of material, considering technical performance, operational safety, and economic feasibility.

Image (F) presents a bench-scale briquetting test, applied to fine charcoal materials, aiming to achieve mechanical standards compatible with metallurgical applications in reduction processes.

Image (G)

Image (H)

Image (I)

Image (G) presents the firing or sintering process of ACO Iron pellets at laboratory scale, used to evaluate their physical-metallurgical characteristics, thermal stability, and behavior under reduction conditions.

Image (H) shows charcoal briquettes produced under high pressure, using HpM-developed specific binders, intended for metallurgical applications in reduction processes, with a focus on mechanical performance, operational safety, and predictable behavior.

Image (I) presents the sintering of iron oxide briquettes derived from metallurgical residues, carried out without the use of binders, demonstrating HpM’s capability to develop structurally stable and thermally safe agglomerates, even from complex residue-based materials.